Reactive Materials

Explosives

Our engineers are experienced with and our facilities can handle conventional explosives based on TNT, RDX, HMX and PETN. We have also created and tested new explosive formulations including APEX, APEX hybrids, and RMBX (reactive multiphase blast explosives).

We have worked on projects implementing:

- directional or focused fragmentation

- in-situ altered fragment geometry

- FAEs (Fuel air explosives)

- Solid obscurant aerosolizing and dispersal

- Mach-stem generation and material interaction

Ballistics

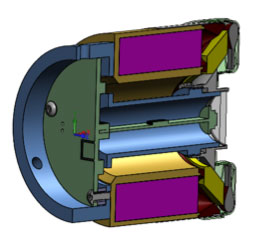

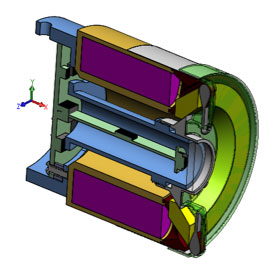

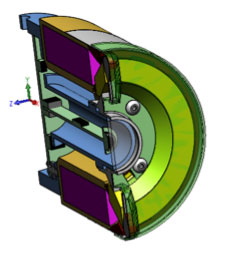

Typically, the projectile is of the most interest in special regard to target interaction. In small and medium caliber ammunition, an inert mass with velocity are used for a kinetic energy kill. EMPI has developed multiple reactive cargo projectiles that deliver additional chemical energy to the target on impact. With industry and government partners, we have designed and constructed numerous variations of complex and simple cargo rounds for multiple purposes.

- Simple cargo rounds nominally contain a metallic shell and a consolidated reactive material (RM) or explosive. The RM and shell are both designed to initiate a strong reaction that causes thermal and pressure damage to the target. For example, EMPI, has developed a reactive 12GA shotgun round based on this simple cargo round concept for breaching applications

- Complex cargo rounds differ in that they contain electronics or delay systems to initiate the reactive material. In some cases, the target is unknown, and the impact conditions vary so the reaction must be started from within the bullet.

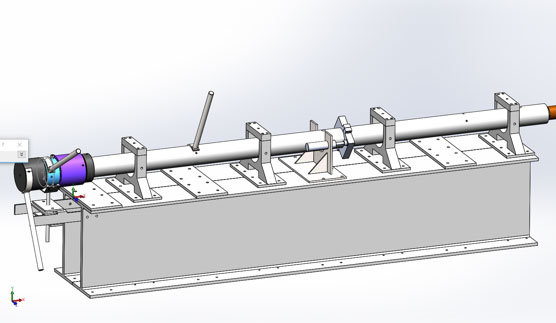

The launching system or gun also has significant value in some applications. The projectile is usually only effective based on a specific velocity range. The gun system must be designed for test or field environments to produce a repeatable muzzle velocity. EMPI has developed multiple projectiles and test gun systems based on the following calibers:

| 0.308” | 30 Cal rifle |

| 0.458” | |

| 0.512” | 50 BMG rifle |

| 0.727” | 12GA Shotgun |

| 0.815” | 20mm Vulcan (electric) |

| 1.496” | 38mm (no case) |

System Integration

Services

EMPI offers a full spectrum of services, from concept development, to feasibility test and product development, to limited product development.

- Pressing

- Melt-cast (TNT based)

- Binder mixing / vacuum casting

- Fuel air explosives (FAE)

- Improvised devices

- Initiators / detonators

- Formulation

- Chemical train design

- Pyrotechnics

- Thermites

- Initiators

- Projectile design

- Propellant design

- Gun design

- Testing

- Flight stability

- Launch survival

- Recoil attenuation

- Target engagement

- Engineering design

- System integration

- CAD modeling

- Materials selection

- Fabrication processes

- Assembly tolerances, interfaces and joints

- Subcomponent evaluation

- FEA static and dynamic simulations

- Hydrocode simulations

- Design of experiments

- High-speed data acquisition

- High-speed digital video

- Material sound speed

- Explosives

- Free-field explosives testing

- Closed Chamber explosives testing

- Pressure field measurements

- Impulse measurements

- High-speed time of arrival (TOA) pins

- High-speed strain and pressure

- Detonation speed

- Synchronized high-speed events

- Ballistics

- Chamber pressure

- Velocity

- High-speed video

- Target interaction

- Reactive Materials

- Calorimetry with variable initiation

- Reaction rate

- Quasi-static pressure

- Impact sensitivity

- ESD sensitivity

Our Team

Due to the uniqueness and complexity of our development work, we employ specific scientists and engineers (PhD, MS, and BS). Typically, project leaders will take responsibility for a technology from concept, to design of experiments or modeling, fabrication, to testing, to data analysis, to reporting and presentation. Our team strives to operate with the best time and cost efficiency.

Differentiators

One advantage of EMPI’s proprietary core technology is its ability to tailor energetic tools and devices for a wide range of customer-driven applications. EMPI offers a range of services giving unique capabilities without the need for multiple subcontractors.

- Flexible test range scheduling and compressed timelines

- EMPI can help the customer develop optimized test protocols

- Engineering analysis, hardware design & rapid fabrication

- Data analysis, technical report – from quick look to formal report

- Lean operations, low overhead > good value

- Experienced staff – combined 40+ years of experience in energetics