We have two primary facilities built to the specific needs of our customers:

EMPI Headquarters in Round Rock, TX

Our headquarter facility houses our engineering, management, and administrative offices. In addition, our headquarters building contains:

- pilot scale chemistry lab for formulation and safety testing.

- lab and high bay area for device and fixture fabrication.

- 10 meter indoor gun range with multiple test barrel calibers and reloading equipment.

- Our on-site machine shop provides precise and fast turn-around capabilities for prototype, test article, and tooling fabrication

EMPI Test Facility, 650 acre test site with laboratory, near Burnet, TX

Our primary test facility includes the following site features:

- 12000 sq. ft building divided into multiple safety zones for explosives, processing, handling and assembly

- Test arena with a climate-controlled control room. The arena is customizable to enable detailed, comprehensive diagnostics including high-speed video, pressure sensors, unconfined momentum traps, witness screens, frag collection packs, etc.

- Heavy equipment such as Skid-steer, Dozers and Front-end Loaders are available onsite for heavy lifting and dirt work.

- Long distance gun range

- Unique underwater testing facilities located on site within the confines of a 150’ deep lake to enable ballistics and explosives testing.

- To support past programs, we have a 10 x 22 ft pontoon shuttle boat that usually serves as a work space and tool barge. Also on the lake, is a custom 10 x 40 ft catamaran with electric winches to raise and lower test fixtures to precise depths. Divers are available on as needed basis to support testing.

Engineering, Modeling, & Design

Let us originate or collaborate on an energetic materials solution for your application. We will design the system using Solidworks, select materials, manage fabrication and assembly, then test the system all at our range in a fast, turn-key operation. We will digest the data and deliver clean and concise documents and presentations with key insights and recommendations for consideration.

EMPI has conducted numerous specialized arena tests for warhead evaluation of pressure, impulse, and fragmentation.

RReaction rate, sound speed, reaction pressure, calorimeter, and total impulse.

Thermal stability tests, bonfire tests, packaged product drop tests, tumble tests, underwater function, bullet impact, drop sensitivity, ESD sensitivity

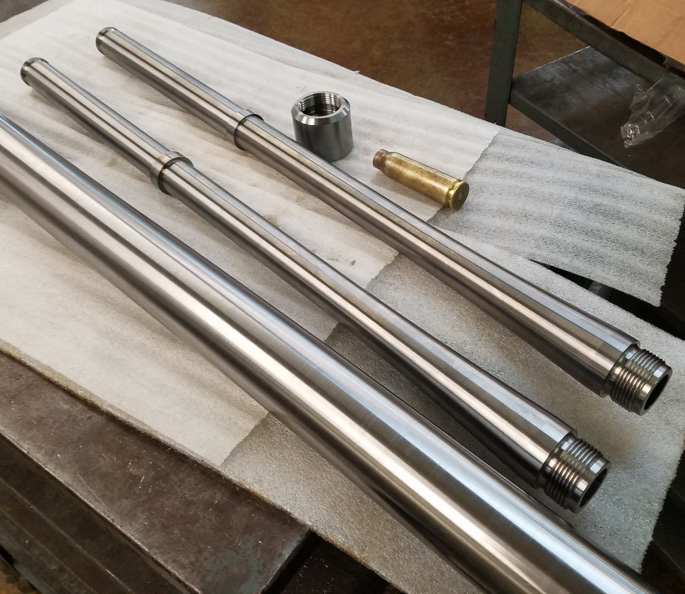

Manual machining capabilities in-house and partnerships with several CNC shops.

We have some explosives in stock at all times that may provide fast turnaround for your project. We can formulate some custom energetic materials in house. We typically design and fabricate our own tooling for molding, pressing, and/or loading. This saves cost and time by avoiding hazmat transport when system are fabricated and tested all at one site on our test range

We have multiple labs that are isolated for safety requirements. The labs can be custom configured for remote or manned operations with energetic materials. Process controls and tooling will be designed and implemented by our engineers. Our skilled technicians will be trained to perform the assembly and fabrication requirements.